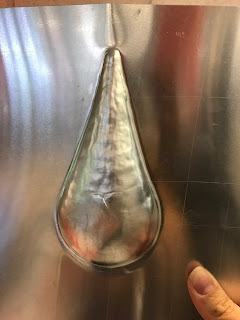

Started off by cutting out a circle from sheet metal using tin snips. I then marked out a horizontal and vertical line intersecting at the center of the circle as well as two circles evenly spaced from the center to act as a guide. I proceeded by hammering the edges of the circle to start off the inward curve of the bowl which created ruffles around the rim. I hammered the ruffles down until they had stretched and molded into shape. I then gradually hammered around the bowl towards the center to make the curve of the bowl more pronounced. I continuously hammered around the bowl until I achieved an even surface throughout the bowl.

|

| The English Wheel was then used to smooth out the surface of the bowl, getting rid of the dimples created by the hammers used. |

Refined the edges of the bowl to make it as circular as possible using a metal hammer and the metal dome.

|

| Finished off the bowl by sanding down the edges for a clean, even edge. |

|

| Created a template to capture the curve of the bowl |